Master-Clip TEFLON® H-EL

Application

- endangered areas, where electrical conductivity is demanded

- extraction of corrosive and explosive gases and fumes in endangered areas

- chemical plants

- paint, wood and paper industries

- extraction of solvents

- pharmaceutical industry

- low pressure applications

Properties

- excellent chemical resistance

- PTFE-film: surface resistivity RO < 106 Ohm

- PTFE is harmless for health

- optimum flow characteristic

- heat and cold resistant, excellent weather resistance

- UV und ozone resistant

- highly flexible and vibrationproof

- extremely compressible ca.1:4

- small bend radius

- outer hose wall of robust material

- inner hose wall with non stick surface

- external steel helix protects against abrasion

- special clamping method guarantees high

- tensile strength between hose material and external helix

- acc. to TRBS 2153 (zone 0, 20) suitable for combustible dusts and gases. Clip ends shall be earthed at both sides, helix pitch shall be < 30 mm and hose shall be connected to static dissipative socket to ensure static dissipation (see register no. 28.12)

- RoHS compliant

Recommended Connecting Elements:

Index Number:

14.4

Product Description

Suction a.blower hose for corrosive media up to +175°C, electr.conductive <106 Ohm

Material

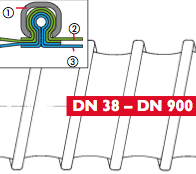

hose wall: inner layer: PTFE-film, electrically conductive, outer layer: Hypalon® coated polyester fabric

external helix: galvanised steel

Temperature Range

- -40°C up to +175°C

- intermittent to +190°C

Construction

- external helix

- outer layer: Hypalon® coated polyester fabric

- inner layer: PTFE-film, electrically conductive < 106 Ohm