Master-PUR H

Application

- extraction of coarse grained particles with high flow volumetric

- for abrasive solids, gaseous and liquid media

- standard hose for industrial vacuum cleaners

- transport of granules

- transport of chips

- suction and transport of paper fibres

- oil spray extraction

- protection hose against mechanical loadings

Properties

- highly abrasion resistant

- resistant to oil and fuels

- gas tight

- good chemical resistance

- free of plastizisers

- free of halogens

- generally good UV and ozone resistance

- very flexible; reduced weight

- small bend radius

- improved pressure and vacuum characteristics

- high tensile and tear strength

- nearly smooth inside

- optimum flow characteristics

- acc. to TRBS 2153 (zone 1, 21) suitable for non-combustible dusts/bulk goods and gases/liquids of low conductivity. Spiral ends shall be earthed at both sides to ensure static dissipation

- RoHS compliant

Recommended Connecting Elements:

Index Number:

1.5

Product Description

PU transport and suction hose, medium weight

Material

hose wall: polyester polyurethane (in comparison with polyether polyurethane more abrasion resistant, acc. to DIN 53516)

spiral: spring steel wire

Temperature Range

- -40°C up to +90°C

- intermittent to +125°C

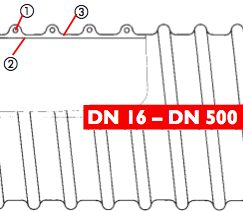

Construction

- immovable cast spring steel spiral

- hose wall: polyester polyurethane

- wall thickness between spirals ca. 1.4 mm